Our Guide To Safety Workwear For Manufacturing Facilities

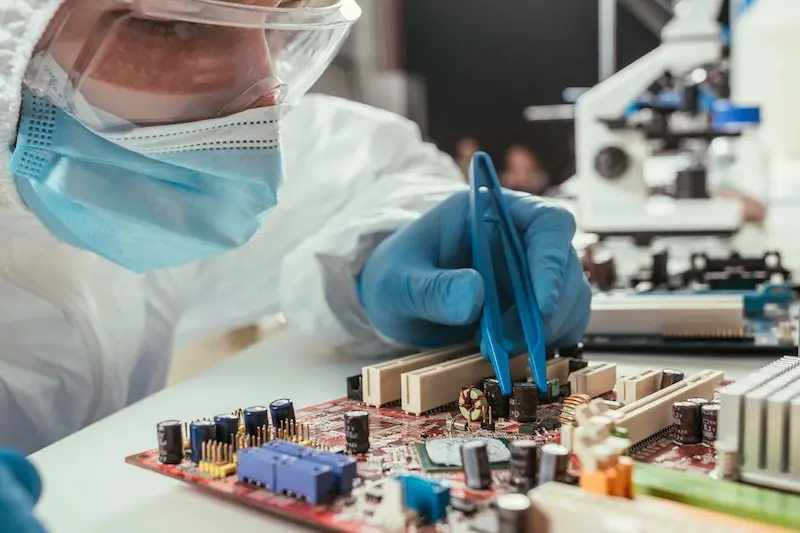

In high-risk industrial settings, selecting the right safety workwear for manufacturing is essential for protecting your team from life-threatening hazards. From moving machinery and airborne dust to sharp tools and chemicals, manufacturing environments demand workwear that delivers both durability and day-long comfort.

In manufacturing environments, generic PPE often falls short, and workers need gear tailored to their specific roles, including accessories like knee pads, belts, and tool pouches that boost safety and functionality.

In this guide, we explore how to identify risks, choose the right gear, and partner with a trusted safety workwear supplier to ensure ongoing protection, compliance, and confidence in the manufacturing sector.

Understanding safety risks in manufacturing environments

Manufacturing environments pose complex, high-risk hazards that require specialised safety workwear tailored to protect workers effectively across diverse industries.

Why general PPE isn’t enough

Manufacturing processes vary widely, from metalwork and fabrication to food processing and chemical handling. This variety means personal protective equipment (PPE) must be matched to the task at hand. While general PPE may offer baseline protection, it often lacks the durability, fit, or functionality needed for prolonged use in demanding manufacturing settings.

Ill-fitting or inappropriate gear can increase the likelihood of injury, discomfort, and non-compliance. When PPE hinders movement or causes fatigue, worker productivity drops, and the risk of accidents rises. The right safety workwear should support comfort and efficiency, helping teams stay focused and protected throughout long shifts.

Each task in manufacturing presents different hazards, requiring PPE designed for the job. For example, fabricators may need cut-resistant gloves, while chemical handlers require full-body suits resistant to hazardous substances. Investing in job-specific safety workwear is critical for reducing risks and meeting workplace safety obligations.

Common hazards that safety workwear should address

Manufacturing is home to a range of hazards that demand high-quality, task-specific protection. Noise exposure calls for robust hearing protection such as earplugs or earmuffs to prevent long-term hearing loss. Chemical spills require resistant gloves, aprons, and suits that protect the skin from corrosive or toxic materials.

When working with sharp tools, protective sleeves, chainmail, or cut-resistant gloves reduce the risk of lacerations. Environments with airborne particulates or fumes necessitate respiratory protective equipment (RPE), such as respirators or filtered masks. Heat-intensive tasks, such as welding, require flame-retardant clothing to protect workers from burns.

Key safety workwear solutions for common risks include:

- Anti-slip safety footwear and overboots to prevent falls on slippery surfaces.

- Protective clothing to guard against biological hazards such as mould or bacteria, particularly important in food manufacturing or healthcare-adjacent sectors.

- Insulated gloves and dielectric footwear to shield workers from electrical shocks.

Additional manufacturing sector risks

Beyond the common hazards, several additional risks must be factored into a comprehensive manufacturing workplace safety plan.

- Electrical hazards – require insulated gloves and dielectric boots that meet relevant safety standards.

- Poor lighting conditions – increase the risk of trips or missteps, making high-visibility clothing (EN ISO 20471 compliant) essential for visibility.

- Moving machinery – presents entanglement and crush risks, requiring snug-fitting clothing and task-appropriate PPE.

- Inadequate lumination in production areas – reduces situational awareness, reinforcing the need for visibility-enhancing workwear.

Addressing these less obvious risks ensures a well-rounded safety strategy, one that equips every employee with gear tailored to their environment and role.

Types of safety workwear for manufacturing environments

To protect workers effectively, manufacturing sites require a full suite of safety workwear designed for the specific risks they present.

Safety workwear for manufacturing roles – what to consider

Matching PPE to job function is essential. Manufacturing workers perform a wide range of roles:

- Welders require flame-retardant overalls.

- Machine operators need cut-resistant gloves and steel-toe boots.

- Line workers and fabricators require job-specific gear for precision tasks.

- Supervisors often need high-visibility clothing and lightweight PPE for mobility.

Workwear should be ergonomically designed and suited to temperature and environmental conditions, whether hot, cold, humid, or dusty. This boosts long-term wearability, improves morale, and increases compliance among staff.

Standards compliance is also vital. Gloves should meet EN388 for cut resistance, while welding clothing must comply with EN ISO 11611. Ensuring your workwear meets certified benchmarks is key to regulatory compliance and worker safety.

Head-to-toe protection – key categories to know

Comprehensive safety begins with protecting the entire body. For the head, bump caps or hard hats are required based on overhead hazards. Eye protection includes safety goggles and face shields designed to resist chemicals or impact.

Hearing protection should be worn in noisy areas to prevent permanent hearing damage. RPE options, such as disposable masks or reusable filtered respirators, are essential in environments with airborne contaminants.

Hands are especially vulnerable in manufacturing, requiring tailored glove solutions: cut-resistant, chemical-resistant, or heatproof, depending on the task. Body protection includes:

- High-visibility vests, flame-retardant jackets, and coveralls.

- Steel-toe boots, metatarsal protection, and slip-resistant soles.

- Chainmail gloves or aprons for high-risk cutting operations.

- Fall arrest harnesses for work at height.

Accessories such as knee pads, utility belts, and ID holders can improve safety and efficiency, especially during physically demanding or precision-based tasks.

Choosing the right safety workwear for your manufacturing facility

Choosing the right workwear is essential to maintaining a safe and productive environment. A trusted manufacturing safety workwear supplier makes it easier to browse certified options and select equipment that fits your facility’s unique hazards and working conditions.

What to prioritise when selecting safety workwear for manufacturing

The best safety workwear aligns with your facility’s specific risks. Consider factors such as:

- Comfort and fit – leading to better compliance and longer wear time.

- Durability and maintenance – durable, easy-to-clean fabrics reduce replacement frequency and downtime.

- Climate suitability – breathable materials for hot conditions, insulation for colder environments.

Partnering with a knowledgeable safety gear supplier helps ensure that each piece of gear meets relevant standards. Always check for compliance certifications before purchase to guarantee safety and regulatory alignment.

Common pitfalls to avoid

Avoid generic PPE approaches that overlook individual roles and sizing needs. Relying solely on office-based procurement staff can result in mismatches between gear and real-world tasks.

Other pitfalls include:

- Delaying the replacement of damaged or expired gear.

- Lack of clear PPE signage in zones with specific requirements.

- Inconsistent enforcement of PPE policies.

Involve your team in the selection process; they’re the end users, and their insights matter. Proper training in wearing, maintaining, and replacing PPE ensures long-term safety and effectiveness.

Why partnering with the right safety workwear supplier matters

A dedicated workplace safety supplier can transform your safety programme, providing expertise, flexibility, and reliable access to compliant workwear. They understand the demands of manufacturing and can recommend suitable products tailored to specific needs.

Work with a supplier that understands manufacturing-specific needs

Specialist PPE suppliers bring insight into industry-specific risks, from heat exposure and chemical handling to hygiene requirements in food-grade environments. They’ll help match PPE to job functions, regulatory frameworks, and workplace layouts.

Flexibility is key. The right supplier can scale your orders with team growth, seasonal changes, or shift expansions. Their understanding of material properties and certifications ensures all products meet safety expectations.

Get ongoing support beyond the sale

Support shouldn’t stop once the gear is delivered. A reliable safety equipment supplier offers:

- Fast replacements

- Inventory management

- New hire support

- Safety audit assistance

- Quick turnaround on orders

These services ensure your operation runs smoothly, reducing the risk of PPE shortages, non-compliance, or lost productivity. Training support also ensures new team members understand how to use and care for their gear properly.

Long-term partnerships ensure you’re always stocked with the right equipment. By preventing gaps in supply and supporting evolving needs, the right supplier keeps your facility safe, prepared, and compliant year-round.

Ark Safety: Your trusted source of safety workwear for manufacturing

When it comes to protecting your team in fast-paced manufacturing environments, Ark Safety is your go-to partner for comprehensive, high-quality safety workwear and PPE.

Our safety wear product range is designed to safeguard your workforce from head to toe, no matter the hazard:

- Cut-resistant gloves protect hands during fabrication and assembly by reducing the risk of lacerations.

- Chemical suits shield workers from corrosive splashes in cleaning, mixing, or processing tasks.

- Anti-slip footwear helps prevent slips and falls on wet or oily factory floors.

- Respiratory protective equipment (RPE) guards against harmful dust, fumes, and airborne contaminants.

- Chainmail gear offers advanced cut protection for high-risk tasks like boning and meat processing.

- High-visibility clothing keeps workers seen in low-light, high-traffic, or busy production zones.

- Fall arrest systems provide essential fall protection for those working at heights.

- Head protection minimises injury from falling objects or low-clearance areas.

- Hearing protection prevents long-term damage in noisy environments like metalwork or machining.

- Eye protection shields from flying debris, chemicals, or sparks in high-risk areas.

- Protective clothing like jackets, aprons, and coveralls offers barrier protection without sacrificing comfort.

- First aid supplies support immediate response to minor workplace injuries.

Contact us today to explore our full product range and discover how we can help your workers stay safe, compliant, confident, and protected – every shift, every task.

Safety workwear for manufacturing FAQs

Q: What is safety workwear for manufacturing?

A: Safety workwear for manufacturing includes specialised PPE like gloves, boots, and flame-retardant clothing designed to protect workers from hazards such as machinery, chemicals, noise, and airborne particles.

Q: Why is job-specific PPE important in manufacturing environments?

A: Job-specific PPE ensures better protection, comfort, and compliance, reducing injury risks compared to generic gear that may not suit the demands of specific manufacturing roles.

Q: What are the key risks that safety workwear should protect against in manufacturing?

A: Manufacturing safety workwear should protect against cuts, slips, chemical exposure, burns, noise, airborne contaminants, electrical hazards, and visibility issues in poorly lit or busy environments.

Q: What types of safety workwear are essential for manufacturing workers?

A: Essential items include cut-resistant gloves, chemical-resistant suits, anti-slip footwear, high-visibility clothing, flame-retardant overalls, RPE, and fall arrest systems, all tailored to specific job tasks.

Q: How can I choose the right safety workwear for my manufacturing facility?

A: Consider factors like task-specific risks, climate conditions, comfort, certified standards (e.g. EN388 or EN ISO 11611), and partner with a trusted safetywear supplier for tailored advice and ongoing support.

Q: What standards should safety workwear in manufacturing comply with?

A: Safety gear should meet relevant certifications, such as EN388 for gloves, EN ISO 20471 for high-visibility clothing, and EN ISO 11611 for welding protection, to ensure compliance and worker safety.

Q: How does Ark Safety support manufacturing facilities with PPE?

A: We offer a comprehensive PPE range, expert advice, fast replacements, next-day delivery on most stock items, and training support to help manufacturing teams stay safe and compliant.

Q: What are the most common types of protective gloves used in manufacturing?

A: Common gloves include cut-resistant gloves for fabrication, chemical-resistant gloves for handling hazardous substances, and heatproof gloves for welding or thermal tasks.

Q: Can high-visibility clothing improve safety in manufacturing plants?

A: Yes, high-visibility clothing helps prevent accidents by increasing worker visibility in low-light or high-traffic zones, especially where forklifts or machinery are operating.

Q: Why should manufacturers avoid generic PPE purchases?

A: Generic PPE often lacks the durability, fit, or certification needed for specific manufacturing tasks, increasing risk. Tailored safety workwear ensures better protection, productivity, and regulatory compliance.